Vietnam’s automobile industry has grown significantly in recent years. The average growth rate of domestically assembled vehicles was approximately 10 percent per year in the 2015-2018 period. With major manufacturers such as Toyota, Honda, Ford, Nissan, and Kia in the Vietnamese market, the number of spare parts suppliers have also invested in the industry giving the sector a much-needed boost.

The motorbike is ubiquitous to Vietnam, but with the country’s fast-growing middle class, car ownership is steadily rising. This growth, however, is likely to be stunted in the short term due to the COVID-19 pandemic but expected to resume in the long run as Vietnam reopens its economy.

Vietnam’s Industrial Policy and Strategy Institute predicts 750,000 to 800,000 vehicles will be sold annually by 2025 up from 288,683 in 2018.

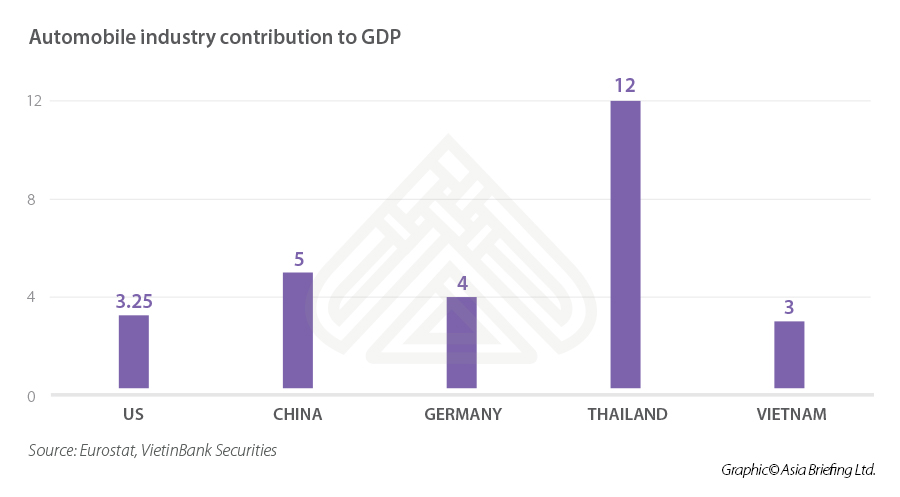

The automotive industry is a major contributor to the GDP of many countries in the world:

As displayed above, with such a high share in Vietnam’s GDP, the automotive industry has always received special attention from the government. There are currently many large automotive assembly and production projects in Vietnam with the aim of not only meeting domestic demand but also tapping into the regional market.

Local conglomerate Vingroup officially inaugurated its Vinfast factory on June 14, 2019, making it the first domestic automobile factory in Vietnam. The factory is not only state-of-the-art but also in line with Industry 4.0 standards.

However, the Vietnamese automotive industry faces stiff competition. Part of the reason for this is the zero-tariff policy between ASEAN countries that Vietnam is part of. Thus imports are cheaper than domestically produced vehicles.

Although Vietnam is one of the four largest automobile manufacturers in Southeast Asia, it has one of the lowest average localization rate in this region (only around 10-15 percent, and is still far behind Thailand, Indonesia and Malaysia).

In addition, the local automobile industry has not been able to invest in core and high technology products such as engine production and transmission systems. Localized parts are mostly of low technology products such as tires, seats, mirrors, glasses, cable harnesses, batteries, and plastic products.

About 80-90 percent of the main raw materials used to manufacture components are still imported. As a result, companies are required to import approximately US$2 billion to US$3.5 billion in components and parts for vehicle manufacturing, assembly, and repair each year.

For this reason, domestic automobile production costs are 10-20 percent higher than in other countries in Southeast Asia. As a result, the cost of cars produced domestically are at a disadvantage compared to completely build units (CBUs) that are imported.

Increasing car ownership

Vietnam imported more than 109,000 CBUs in the first nine months of 2019 with a turnover of US$2.4 billion as per official statistics. Compared to the same period in 2018, imported cars increased by 267 percent in volume and 257 percent in value.

Cars with less than nine seats led imports – with about 75,848 vehicles valued at US$1.5 billion. This shows the increasing purchasing power and the changing demands of customers. In addition, the vehicles imported from the EU mainly come from Germany. As per the General Department of Vietnam Customs in 2018, 1,197 imported cars from Germany were registered in Vietnam. Germany’s ZF Friedrichshafen inaugurated its first plant producing chassis modules for cars in Haiphong in November 2019.

—————————

This article is produced by Vietnam Briefing, a premium source of information for investors looking to set up and conduct business in Vietnam. The site is a publishing arm of Dezan Shira & Associates, a leading foreign investment consultancy in Asia with over 27 years of experience assisting businesses with market entry, site selection, legal, tax, accounting, HR and payroll services throughout the region.