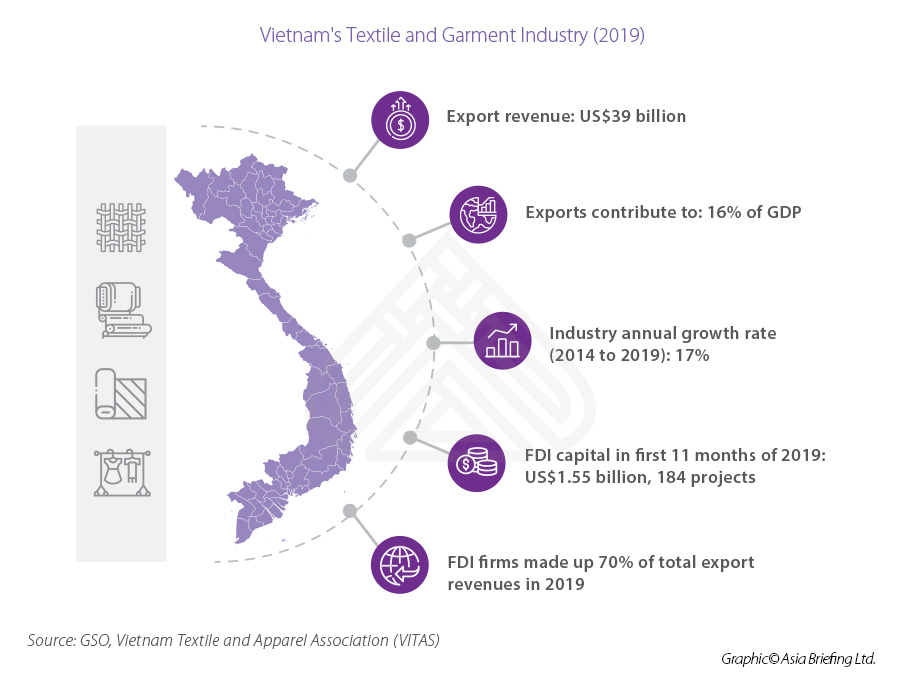

The garment and textile industry is one of the key industries in Vietnam with the second-largest export turnover in the country. In 2019, the industry’s export value contributed to 16 percent of total GDP. In the past five years, the textile industry has continuously grown at an average rate of 17 percent annually.

In 2019, Vietnam’s garment and textile industry earned US$39 billion from exports, a year-on-year increase of over 8.3 percent, according to the Vietnam General Statistics Office. Garment manufacturing accounts for the majority of businesses, at 70 percent. Major factors driving the growth of the market are low labor costs and growing textile exports to the EU, the US, Japan, and South Korea.

Industry overview: 3 sub-sectors

Vietnam’s garment and textile industry consist of 3 sub-sectors: upstream sector (fiber production), midstream sector (fabric production and dyeing), and downstream sector (garment manufacturing).

Sub-sectors that produce fibers or fabric are mainly used for domestic consumption because of the low quality. Downstream sector of garment manufacturing accounts for around 70 percent of the total apparel and textile sector in Vietnam with Cut-Make-Trim (CMT) models being the main activities. In 2019, CMT accounted for about 65 percent of total exports, while the more advanced business models, like Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) accounted for only 35 percent.

The US, Europe, Japan, and South Korea are the main export destinations of Vietnam’s textile and garments products. Although Vietnam has a huge potential for cotton cultivation and production, the textile industry imports most of the cotton inputs. In 2019, Vietnam imported up to 89 percent of fabrics, of which, 55 percent were from China, 16 percent from South Korea, 12 percent from Taiwan, and 6 percent from Japan.

Growth factors – increased market access and low labor costs

Increased market access through free trade agreements (FTAs_ and technology are major growth drivers for the garment and textile industry. Vietnam’s bilateral and multilateral FTAs continue to provide Vietnamese manufacturers access to new markets, minimizing the effect of growing trade protectionism. With new FTAs in effect such as the Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP) and Vietnam-EU FTA (EVFTA), new markets will lead to higher exports and push manufacturers to develop the industry’s supply chain so that they can take full advantage of the preferential tariffs and increase the competitiveness of their products.

Further, manufacturing shifts from China to Vietnam due to their labor cost advantage and skilled workers will also help expand the textile and garment industry.

Going forward, market access alone will not be enough to generate growth and Vietnamese manufacturers would also need to invest in technology – especially Industry 4.0 technologies – to increase productivity, and quality to remain competitive.

Foreign direct investment

According to the United Nations Conference on Trade and Development (UNCTAD), in the first 11 months of 2019, Vietnam attracted FDI capital to the garment and textile industry with a value up to US$1.55 billion for 184 projects. Investments were led by Hong Kong (US$447 million), Singapore (US$370 million), China (US$270 million), and South Korea (US$165 million).

Tay Ninh, (US$464 million, 16 projects), Quang Nam (US$107 million, 10 projects), Nghe An (US$210 million, 3 projects), and Thua Thien Hue (213 million, 2 projects) are localities that attracted most FDI in 2019 due to government incentives and their proximity to major economic hubs in the Southern and Central parts of Vietnam.

FDI firms made up 70 percent of total garment and textile exports in

2019. In recent years, foreign investment has shifted from mainly CMT activities to more upstream sectors such as fabric productions and dyeing. In 2019, more than 80 percent of FDI in the industry consisted of manufacturing fabrics and raw materials projects.

Besides capital, these FDI firms have provided competition pressure and spill-over benefits that stimulate innovation and growth of domestic producers, as well as help scale-up the industry ‘s capacity in the past three decades.

—————————

This article is produced by Vietnam Briefing, a premium source of information for investors looking to set up and conduct business in Vietnam. The site is a publishing arm of Dezan Shira & Associates, a leading foreign investment consultancy in Asia with over 27 years of experience assisting businesses with market entry, site selection, legal, tax, accounting, HR and payroll services throughout the region.